High Specification Salt Inhibitor

When a new damp-proof course has been installed it will normally be necessary to hack of salt contaminated plaster and to replaster using a salt-resistant render. Such a render can be formed by using a mixture of sharp sand and cement guaged with diluted No Hydro Salt Inhibitor.

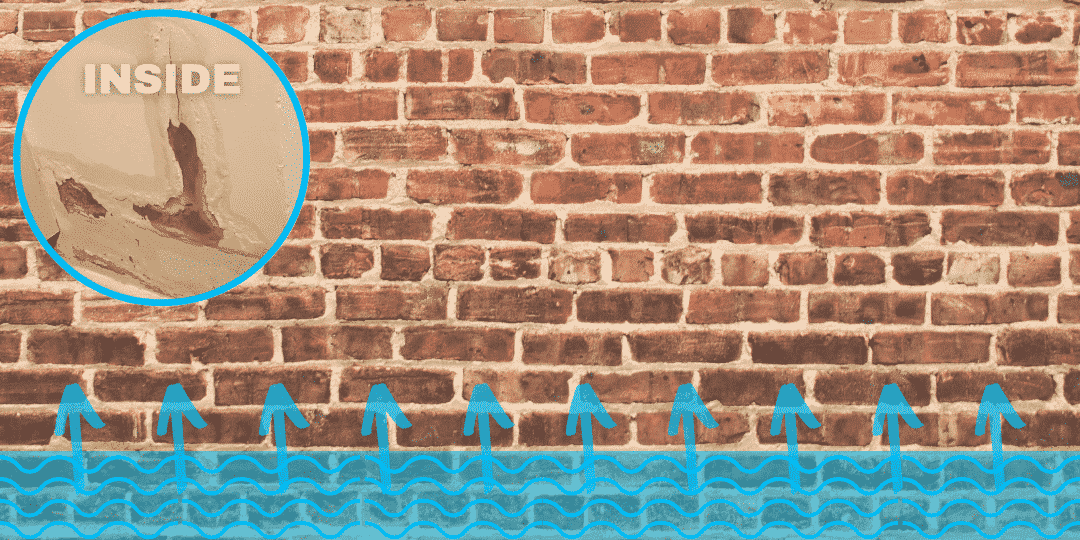

Rising Damp

The groundwater rising contains ground salts which are nitrates and chlorides. It is these ground salts that cause the contaminated plaster. These ground salts are hygroscopic and naturally absorb and hold moisture causing the walls to become highly saturated, contaminating plaster, and causing the skirting boards to decay and rot as they are against damp walls.

CK Plastering –

best salt inhibitor on the market

Toner Damp Proofing Ltd –

Used this when replastering after DPC Installation in the new render to prevent salt contamination from the treated walls, the walls are perfect with no damp or salt contamination problems.